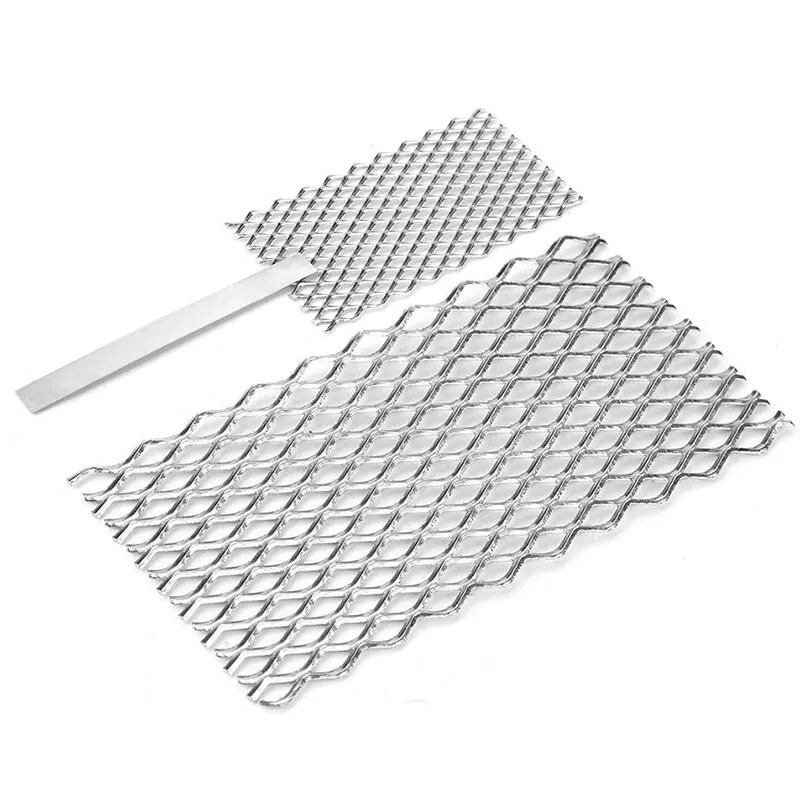

Mmo Platinum Titanium Anode

Keywords:

Category:

Description

Product description

MMO Titanium anode is used for salt chlorinator. The cell of a salt chlorinator is the part that actually converts the salt (NaCl) into chlorine and consists of a plastic housing and electrodes. The electrodes are usually made of titanium, a highly corrosion-resistant material, and the anode is usually coated with ruthenium or iridium oxide. The composition of this coating plays an important role in both the efficiency of the cell's chlorine production and its expected lifetime.

Specification: customized according to customer drawings.

1. Coating Metal: Titanium-based ruthenium-iridium coated electrode.

2. Current Density: 2000A/m2.

3. Temperature: <50℃

4. Salt solution concentration: 3-5%.

5. Coating Thickness: 6-10 micron.(10g/m2)

Application

1)Zinc plating, including steel plate galvanizing;

2)precious metal plating (including gold plating, silver plating, palladium plating, etc.);

3)hard chrome plating; nickel plating;

4)tin plating (steel plate tin plating);

5)copper plating, copper foil production, copper foil post-treatment, applied to aluminum foil anodization in liquid conductivity generation tanks.

6)Chlorine generators.

Proper maintenance of salt chlorinators

—To maximise the life of your salt chlorinator, consider the following tips.

—Use with reverse polarity electrodes to greatly reduce scale build-up on the cell and extend the life of the chlorinator.

—Maintain a consistent salt level (typically 2700-3900 ppm)

—Clean the chlorinator chamber at least once a quarter or as required

—Avoid cleaning the chlorinator cell too often

—Turn off the pool unit during thunderstorms to avoid damaging power surges

—Keep calcium levels as low as possible and still meet the guidelines set by the pool equipment manufacturer

Advantages of titanium anodes compared with the traditional process of applying platinum-plated electrodes in alkaline copper as follows:

1. High current efficiency, good corrosion resistance, long anode life, high current density (up to 10000 A/m2).

2. Energy saving: As we all know, platinum-plated electrode is a high oxygen potential (1.563V, compared with mercurous sulfate) electrode, while titanium anode with precious metal oxide coating is a low oxygen precipitation overpotential (1.385V, compared with mercurous sulfate) electrode, which is easier to precipitate oxygen in the anode precipitation zone. As a result, the tank pressure is relatively low during the electrolysis process, thus saving more electrical energy.

This phenomenon is evident in the alkaline copper plating solution for copper foil post-treatment.

3. No pollution:Precious metal oxide coated titanium anode coating is a ceramic oxide of precious metal iridium, which is a rather stable oxide, almost insoluble in any acid or alkali, and the oxide coating is only 18~40μm, so the oxide content of the whole coating is very small. Therefore, the precious metal oxide coated titanium anode will not pollute the plating solution and is basically the same as platinum plated electrode.

4. High cost performance:In order to achieve the same service life of platinum-plated electrode (coating thickness 3.5μm), the price of precious metal oxide coated titanium anode is about 80% of that of platinum-plated electrode. Precious metal oxide coated titanium anode has good electrochemical stability in alkaline copper plating electrolyte, and has excellent electrocatalytic activity and durability.

5. In the printed circuit board industry, copper plating requires pulse-periodic reverse current (PPR). We know that in an environment containing chlorides in sulfuric acid systems, platinum-coated titanium anodes will flake off the platinum layer after working for a period of time. However,precious metal oxide coated titanium anodes can effectively change this situation.

6. Low maintenance cost: Compared with traditional soluble electrodes (graphite and lead alloy electrodes), precious metal oxide coated titanium anodes do not require frequent stoppages for cleaning and replenishment of anodes, nor do they require frequent replacement of anode packages and recoating of anodes, which improves productivity and reduces labor costs;

7. Under the same working conditions, the lifetime of titanium anodes with precious metal oxide coating depends on the working current density, temperature and composition of the plating solution.

Product Consultation

Weian Wire Mesh Manufacturing

Contacts: Mr. Cui

Tel: 0086-19932398873

E-mail: john@weianexpandedmesh.com

WhatsApp: +8619932398873

Address: East Huangcheng Industrial Park, Anping county, Hengshui City, Hebei Province

WeChat QR code

Copyright © 2023 Anping Wei'an Wire Mesh Manufacturing Co., Ltd.