Flue Gas Desulphurization

Flue Gas Desulphurization

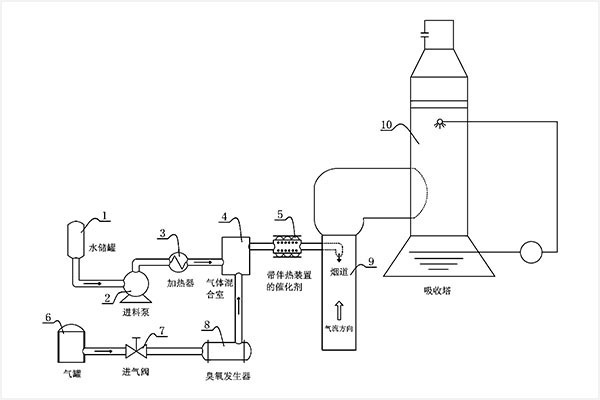

In the production process of electric power, petrochemical, chemical, coal, metallurgy, glass, alumina, ceramics, refractory, cement and other industries will produce many types of Nitrogen Oxides (NOX), including Nitrous Oxide (N2O), Nitric Oxide (NO), Nitrogen Dioxide (NO2), etc. Among them, the NO and NO2 are common air pollutants. So, the flue gas denitrification is critical important and requisite measure for the enterprise.

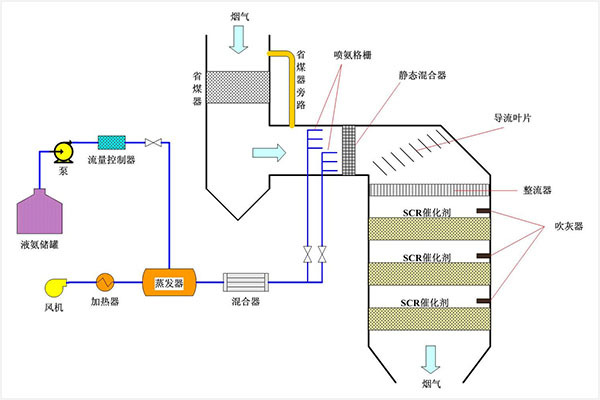

The main denitrification treatment methods include Selective Catalytic Reduction (SCR), Selective Non-Catalytic Reduction (SNCR) and so on. Plate type, honeycomb type and corrugated type catalysts are main types of SCR. Plate type catalysts have various advantages than the other two types.

SCR plate catalyst metal mesh base plate is the prototype of plate catalyst production. The plate catalyst is made of stainless steel metal plate by stamping and stretching, and after processing, it forms a mesh shaped sheet material object; After the mixture of TiO2, V2O5, etc. is adhered to the stainless steel mesh, pressed and calcined, the catalyst plate is assembled into a catalyst module which is beautiful, solid and beautiful.

FLUE GAS DESULFURIZATION AND DENITRIFICATION

|

MATERIAL |

LWD*SWD |

THICKNESS |

STRAND |

WIDTH |

LENGTH |

|

SS430 |

2.3 × 4.5 |

0.45 |

0.6 |

485 |

3000 |

|

SS430 |

2.3 × 4.5 |

0.4 |

0.5 |

502 |

3000 |

|

SS430 |

2.3 × 4.5 |

0.35 |

0.3 |

510 |

2500 |

Related Products

Weian Wire Mesh Manufacturing

Contacts: Mr. Cui

Tel: 0086-19932398873

E-mail: john@weianexpandedmesh.com

WhatsApp: +8619932398873

Address: East Huangcheng Industrial Park, Anping county, Hengshui City, Hebei Province

WeChat QR code

Copyright © 2023 Anping Wei'an Wire Mesh Manufacturing Co., Ltd.