Lightning Strike Protection

Lightning Strike Protection

Carbon fiber composite materials have been the main materials for aircraft manufacture. But the composite material is a poor conductor of the current and easy to be damaged in the lightning strikes. The damage of glass fiber blades caused by lightning attack happen a lot at the front and near edges of the blades, but there are not any protective measures for carbon fiber blades, the damage part is the main layer of bearing the load, because these parts is conducting carbon.

Copper and Aluminium micro expanded metal covers on the surface of composite material to dissipates the lightning strikes, prevent lightning striking damage, supply protection to composite material, and extend aircraft critical components' safe.

It is widely used in the aerospace for aircraft manufacturing at fuselage, wing, engine compartment, flaps, wing tip, even the rotating blades and body parts of the helicopter.

Micro expanded mesh Advantage:

-Exceptionally Long Life

-Outstanding mechanical strength (Anti-ravel and Flexible)

-High conductivity, apertures reach conductivity of 200,000 amps

-Reduced Material Costs, Installation Costs, and Maintenance Costs

-Good lightning protection and electromagnetic interference prevention

-Excellent shielding and heat transfer performance

-Single structure, formed all by one piece, eliminating the possibility of mesh breakage and sudden resistance fluctuations

-Uniform openings and thickness, making the surface smooth and adhesives easier to penetrate

-Flexibility in design and weight according to different structures and requirements

-Precision expanded metal mesh product for specialist industry needs

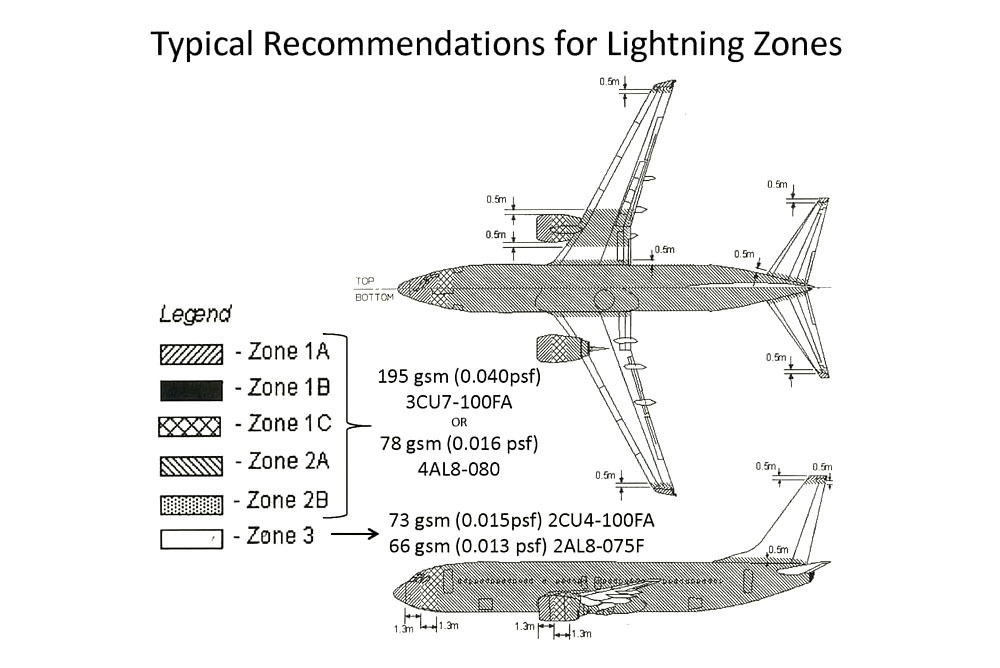

According to the SAE ARP 5414 standard, the aircraft surface is divided into three zones: zone 1A, Zone 1B-1C-2A-2B and zone 3. and we will recommend the different types of micro expanded metal mesh for different zones for the best performance.

Zone 1B and 2B – double layer of 195 g/m2 or 420 g/m2 copper mesh. Because the continuous current will enlarge the damage area and deepen the damage depth.

Zone 1A – 195 g/m2 copper mesh for protection.

Zone 1C – 195 g/m2 or 140 g/m2 copper mesh

Zone 2A – 107 g/m2 copper mesh

Zone 3 – 78 g/m2 copper/aluminum mesh

|

WEIGHT |

MATERIAL |

SWD |

THICKNESS |

OPEN RATE |

LENGTH |

|

49 |

铝AL1060 |

1.0 |

0.10 |

64% |

80–300 |

|

78 |

铝AL1060 |

0.5 |

0.15 |

68% |

80–300 |

|

136 |

铝AL1060 |

1.25 |

0.15 |

63% |

80–300 |

|

36 |

铝AL1060 |

1.3 |

0.04 |

64% |

80–300 |

|

78 |

铜箔COPPER FOIL |

1.3 |

0.10 |

85% |

80–300 |

|

107 |

铜箔COPPER FOIL |

0.7 |

0.13 |

78% |

80–300 |

|

140 |

铜箔COPPER FOIL |

1.5 |

0.13 |

77% |

80–300 |

|

195 |

铜箔COPPER FOIL |

1.8 |

0.13 |

70% |

80–300 |

|

390 |

铜箔COPPER FOIL |

2 |

0.33 |

55% |

80–300 |

|

420 |

铜箔COPPER FOIL |

3 |

0.33 |

53% |

80–300 |

|

815 |

铜箔COPPER FOIL |

2.25 |

0.25 |

64% |

80–300 |

|

78 |

铜箔COPPER FOIL |

2.4 |

0.05 |

85% |

80–300 |

|

107 |

铜箔COPPER FOIL |

2.5 |

0.05 |

78% |

80–300 |

|

140 |

铜箔COPPER FOIL |

0.8 |

0.08 |

77% |

80–300 |

Related Products

No data available

Weian Wire Mesh Manufacturing

Contacts: Mr. Cui

Tel: 0086-19932398873

E-mail: john@weianexpandedmesh.com

WhatsApp: +8619932398873

Address: East Huangcheng Industrial Park, Anping county, Hengshui City, Hebei Province

WeChat QR code

Copyright © 2023 Anping Wei'an Wire Mesh Manufacturing Co., Ltd.