Wind Turbine

Wind Turbine

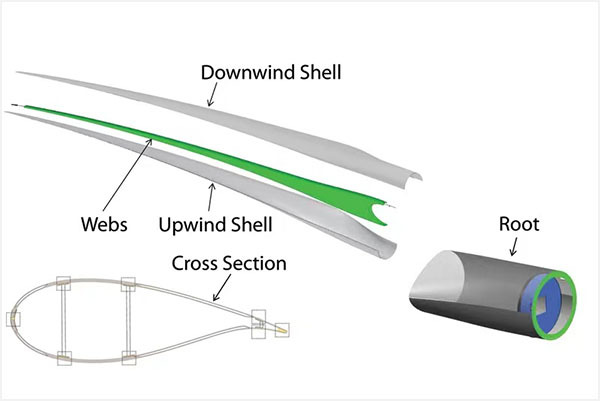

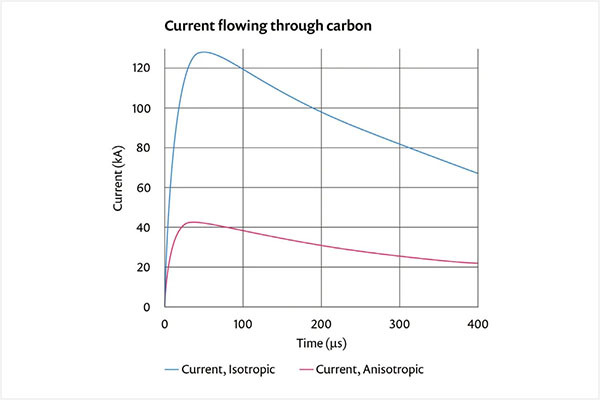

Carbon fiber materials have been the main materials for wind turbine blade manufacture.As the ideal material for Blade of Wind Turbine Lightning Strike Protection, when struck by lightning, an unprotected wind blade experiences an electric arc from the point of contact through conductive components to the root of the structure, and parts may reach temperatures of up to 30,000 degree and possibly cause the blade exploded.

Copper/Aluminium Expanded Metal Foils protect these composite structures from lightning strikes and ensure the functionality of the components.

We have developed an extensive range of products and offer expanded metal in brass, phosphor bronze, and copper in various sizes, widths, and meshes. Copper expanded metal is used for Wind Turbine Lightning Strike Protection, industrial filter applications, (petrol)chemical industry, aeronautics, automotive and electric fields. Their superior strength and versatile size lead to improved performance at a minimum cost.

Applications

Micro expanded mesh Advantage:

-Exceptionally Long Life

-Outstanding mechanical strength (Anti-ravel and Flexible)

-High conductivity, apertures reach conductivity of 200,000 amps

-Reduced Material Costs, Installation Costs, and Maintenance Costs

-Good lightning protection and electromagnetic interference prevention

-Excellent shielding and heat transfer performance

-Single structure, formed all by one piece, eliminating the possibility of mesh breakage and sudden resistance fluctuations

-Uniform openings and thickness, making the surface smooth and adhesives easier to penetrate

-Flexibility in design and weight according to different structures and requirements

-Precision expanded metal mesh product for specialist industry needs

|

MATERIAL |

COPPER |

|

THICKNESS |

0.05 mm |

|

STRAND |

0.1 mm |

|

SWD |

0.5–1.752 mm |

|

LWD |

0.8mm -2.5 |

|

WIDTH |

941 mm |

|

LENGTH |

≥ 80 m |

|

THICKNESS |

0.1 mm ± 10% |

|

WEIGHT |

145 g/m2 |

|

RATES |

55% |

Related Products

Weian Wire Mesh Manufacturing

Contacts: Mr. Cui

Tel: 0086-19932398873

E-mail: john@weianexpandedmesh.com

WhatsApp: +8619932398873

Address: East Huangcheng Industrial Park, Anping county, Hengshui City, Hebei Province

WeChat QR code

Copyright © 2023 Anping Wei'an Wire Mesh Manufacturing Co., Ltd.